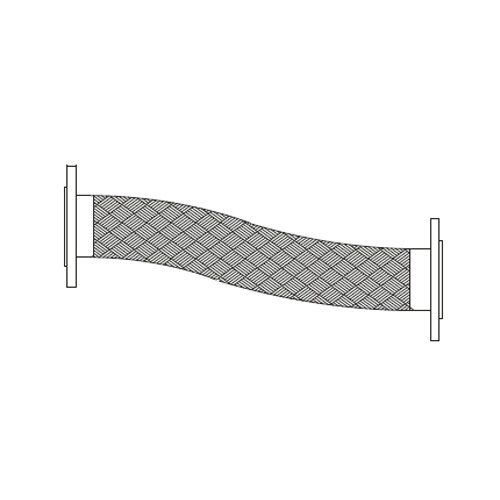

Metallic Expansion Joint

Product Details:

X

Product Description

Why Expansion Joints are Required

- While designing pipelines, a main artery of the modern industry, planners always face many obstacles : the expansion and contraction of pipes caused by temperature changes both external and internal, vibrations generated from machine operation and other stress imposed on the pipelines by wind or in some cases by earthquake. Therefore, protection from these hazardous elements is always of major interest to the pipeline engineers.

- To absorb pressure from expansion, contraction and the vibration of pipes, flexibility is key. One of the most effective flexible elements is the metallic bellows type expansion joint, which is currently widely used due to continued developments and improvements in the performance and design technique.Parts and Features of Expansion Joints

- Bellows : After welded Piping forming with high-quality stainless steel sheets, bellows are produced through hydraulic forming or roll forming. And sometimes the bellows are heat treated to eliminate the remaining welding stress on the welded part or to remove the remaining stress generated during forming.

- End Pipe: To facilitate connecting and fitting into the ends of bellows, the end pipe is normally made with the same material that is used for the pipeline, and also to the same size as the pipeline.

- Liner/Internal Sleeve: A device which minimizes contact between the inner surface of the bellows of an expansion joint and the fluid flowing through it. It prevents vibration, and erosion of theBellows.

- Flange: Customer can choose a flange standard from among BS 10 Table D / ANSI / DIN / IS or any other standard.

- Tie Rod: The rods protect a device from excessive stretching and prevent the dislocation of pipelines. They also stabilize pipelines by absorbing thrusts.

Product details

|

Burst Bend |

400 Kg/cm2 |

|

Dynamic Bend Radius |

100 mm |

|

Max Working Pressure |

100 Kg/cm3 |

|

Nominal Size |

1/4 Inch (6 mm) |

|

Static Bend Radius |

25 mm |

|

Test Pressure |

150 Kg cm2 |

|

Material |

Stainless Steel |

|

Brand |

Easyflex |

|

Application |

Structure Pipe |

Enter Buying Requirement Details

Other Products in 'Metallic Expansion Joints' category

|

KANWAL INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |