Showroom

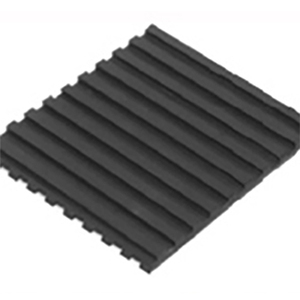

We provide highly-durable range of Expansion Joint And Anti-Vibration Pads designed using high-grade rubber, plastic and other raw materials as per the global quality norms. These products are strong products widely used for holding parts together while absorbing the temperature. These pads are designed to induce expansion and contraction of the building materials. In addition, they are also ideal for absorbing the thermal expansion and contraction in cryogenic lines. These Expansion Joint And Anti-Vibration Pads are available in a range of sizes and lengths for catering to the demands of the market.

|

KANWAL INDUSTRIAL CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |